Precise control during the brewing process and fermentation is crucial to producing good beer. Various instruments are used to measure and monitor parameters that influence the entire process. These instruments include the beer spindle or refractometer, the thermometer and the pH meter.

Measuring the original wort content

The beer spindle and the refractometer are tools for measuring the original wort content. The beer spindle, also known as a hydrometer, enables the density of the beer wort to be measured before and after fermentation. The refractometer, on the other hand, uses the refractive behavior of light to determine the original wort content and can also precisely measure the alcohol content during fermentation.

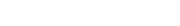

Refractometer

A refractometer is based on the principle of light refraction. The great advantage of this measuring instrument is that you only need one or two drops of sample and therefore have to "waste" less of your own beer. To measure your original gravity, take one or two drops of sample from your fermentation vessel. Now wet the measuring surface with the sample liquid and hold the refractometer up to the light to be able to read the value from the scale. Note that after fermentation, the measured sugar value is falsified by the alcohol and must be converted.

You can find a refractometer calculator here.

| | | | | |

| | | | | |

| | | | | Extensive measurement options (e.g. IBU, vol.%, pH, sugar, FAN) |

| | | | | Varies depending on the measurement |

| | | | | |

| | | | | |

Beer spindle / Hydrometer

A beer spindle, also known as a hydrometer, is a floating body that is immersed to different depths in the liquid to be measured, depending on the density or extract content. The higher the extract content, the higher the spindle floats. A beer spindle measures the sugar content of a liquid in percent by weight in the unit °P (degrees-Plato).

To measure the original gravity with a spindle, you need a measuring cylinder that is almost full with the beer to be measured. Make sure that the sample liquid is at 20°C! When buying, you should choose the right cylinder size for the corresponding spindle. Then carefully lower the spindle into the liquid and rotate it to remove any air bubbles adhering to the spindle. As soon as the spindle stops rotating in the liquid, the original wort can be read off.

Measuring the temperature

Thermometers are essential throughout the brewing process. They monitor the temperature of the mash during the mashing process to ensure the temperature optima of the working enzymes. They are also important during fermentation to ensure optimal yeast activity. Fluctuations can impair yeast activity and produce undesirable aromas in the beer.

Whether you use a simple rod thermometer or a digital one, correct measurement is crucial. Try to measure the temperature while stirring to ensure a consistent temperature distribution during the measurement. Furthermore, the temperature should not be measured directly on the surface, but the temperature probe must be held as far as possible into the center of the wort.

Many fermenters, such as the EasyBrew FB30, are already equipped with a thermometer to monitor the temperature during fermentation. During fermentation, the thermometer should be positioned as centrally as possible in the tank. It is best to have several thermometers, as different temperatures can occur in different parts of the fermentation tank. For example, the temperature in the cone, where the yeast collects, is warmer than in the rest of the tank due to fermentation activity.

| | | Digitale Probe Thermometer | with stainless steel probe | (fermentation thermometer) |

| | | | | |

| | | | | |

| | | | | |

| | | | | |

| | | | | |

| | | | | |

Measuring the pH value

A pH meter or pH test strips are another important tool for controlling the brewing process. We check the pH value of the mash after mashing as, in addition to the temperature, this is an optimum pH value for the enzymes to saccharify.

You can find pH meters here.

Measuring starch degradation

To ensure complete saccharification of the starch, an iodine sample should be taken. An iodine solution is required for this.

The iodine sample is taken as follows:

Shortly before the end of the last rest, take a tablespoon of mash from the brew and place it on a white plate. Now drip 1-2 drops of the iodine solution onto the plate with the mash and stir the two liquids together.

If the wort retains its color or only turns slightly yellowish/orange, the saccharification of the starch is complete and the brew is therefore iodine-normal.

If the wort turns black/blue or purple, starch is still present and the brew is iodine positive.

You can find the iodine solution here.

Conclusion

The use of these instruments is crucial to precisely control the brewing process and ensure the quality of the beer. They allow brewers to monitor and adjust parameters such as original gravity, alcohol content, temperature and pH to achieve the desired beer profile. The combination of these tools gives brewers the ability to perfect their craft beer and create unique flavors.

-Jan Dubenkropp

Braumarkt Beer Brewing Guide