Beer Brewing Guide - Step 5: Whirlpool & Cooling

Reading time: 3 minutes

Whirlpool

After boiling, the whirlpool is used to remove solid particles, the so-called hot trub. This consists of proteins and other solid particles that flocculate during the boiling of the wort and settle at the bottom of the brewing kettle.

The whirlpool effect is created using a mash paddle, for example, by stirring the wort into a vortex. Then remove the paddle from the wort and leave it to rest for 10 to 20 minutes. Take care not to stir the wort too much to avoid excessive oxygenation.

During this time, the hot trub settles on the bottom of the kettle in a cone shape, the so-called trub cone. As the drain tap of the brewing kettle is located slightly above the bottom of the kettle, the hot trub remains on the bottom.

The effects of the hot trub on the beer are diverse. If the hot trub is not removed, it can leave undesirable flavours and bitterness in the beer. It can also affect the shelf life and produce cloudy beer. Proper removal of hot trub results in a clearer and more flavourful end product and helps to keep the beer fresher for longer. Therefore, carefully draining or filtering the wort to remove the hot trub is an essential step for brewers to produce a high quality beverage.

Cooling

There are various reasons for cooling the wort after boiling.

Firstly, beer wort is not sterile and at temperatures below 65 °C, bacteria and wild yeasts can spread and cause defects in the beer. The wort should therefore be brought to the pitching temperature (the temperature at which yeast is added) as quickly as possible to avoid infections of all kinds.

Cooling also reduces the oxidation time of our wort and, above all, controls post-isomerisation. Post-isomerisation describes the bitterness that is released from the hops after boiling at <80°C.

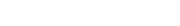

The wort can be cooled using an immersion wort cooler, or cooling coil, for example. Cold running water is connected to one end of the cooling spiral, which has a long contact time with the wort due to the spiral shape of the cooler and therefore cools it quickly.

In a plate wort cooler, the beer flows in the opposite direction to the cold water. The wort cooler has 30-60 very thin plates inside, which separate the beer from the water. Due to the large contact surface of the two liquids, the wort is cooled to the desired brewing temperature very quickly. The more plates the wort cooler has, the faster the cooling capacity. Make sure that the plate wort cooler is cleaned properly after use, as a biofilm can easily form in the plates, posing a considerable risk of infection for your beer! The use of surfactant-free cleaning agents is recommended here. You can find out more about this in our blog entry "Cleaning"!

Cooling the wort is an important step for the reproducibility of recipes and is highly recommended for infection-free and speedy work!

| EasyBrew 30 Wort cooler | Wort cooler compact | Basic

| Plate heat exchanger 60 Plates | EasyBrew Counterflow chiller |

System | Immersion - Wort cooler | Immersion - Wort cooler | Immersion - Wort cooler | Plate heat exchanger | counterflow |

Connection |

/ Open line

| Thread |

/ Open line | Hose nozzle | Thread and Tri-Clamp |

Cleaning the system | easy | easy | easy | hard | easy |

External system | X | X | X | ✓ | ✓ |

Price | 59,95€ | 69,95€ | 89,95€ | 139,95€ | 149,95€ |

Braumarkt Beer Brewing Guide

Step 1: Malt Milling

Step 2: Mashing

Step 3: Lautering

Step 4: Boiling

Step 6: Fermenting

Step 7: Bottling

Step 2: Mashing

Step 3: Lautering

Step 4: Boiling

Step 6: Fermenting

Step 7: Bottling