Beer Brewing Guide - Step 2: Mashing

Reading time: 3 minutes

The mashing process is a central step in beer production in which malt and water are mixed to form a mash. The starch contained in the malt is converted into fermentable sugars in this step. These later serve as an energy source for the yeast, which uses them to produce energy, alcohol and carbon dioxide during fermentation.

Step 1: Malt selection and preparation

Before the mashing process can begin, careful selection and preparation of the malt is crucial.

If you have not yet familiarised yourself with the raw materials, you can also order ready-made malt packs with great recipes here.

Malt can be made from different types of grain such as barley, wheat, rye or oats. The malt grains are soaked, germinated, kilned and crushed in the brewery. The mill crushes the malt into a grist of coarse flour and husks (this is the husk of the grain, which is important for the lautering process) and is then mashed.

Also read our article on grinding oft he malt

Step 2: Mashing in

The actual mashing process begins with mashing in, in which the milled malt and water are mixed at a certain temperature in a mash tun. The mixture of malt and water is known as the mash. Mashing should take place at temperatures above 60°C so that the protein breakdown is not too strong, which would otherwise lead to foamless beers.

Step 3: The resting times

During this resting phase, the enzymes in the malt have the opportunity to break down the starch contained in the malt grains into different types of sugar, especially maltose. This step is crucial as it influences the flavour and sugar composition of the final beer.

Mashing is followed by the resting times, which last 30 to 60 minutes depending on the recipe. Most resting programmes include a maltose rest and a saccharification rest. During the maltose rest, the β-amylases work at 60-65 °C (due to the harvest, the optimum temperature is currently 64 °C) to convert starch into maltose. Maltose forms the majority of fermentable sugars for the yeast and its content determines the final degree of fermentation of the beer. The resting time here is typically between 20 and 45 minutes, depending on the beer style. Shorter rests lead to sweeter beers, longer ones to drier, more alcoholic beers. During the saccharification rest, the α-amylase works optimally in the temperature range of 70-75 °C. This is where the remaining starch is broken down and longer-chain sugar molecules, known as dextrins, are formed. These are not metabolised by the yeast and remain in the finished beer, giving the beer residual sweetness and a full flavour.

Step 4: Temperature control

Temperature control is very important during the resting period. If the mash becomes too hot or too cold, this can affect enzyme activity and lead to undesirable results.

Step 5: Ending the mashing process

After the resting time is complete, the mash is subjected to a one last step before lautering. At a temperature of 75-78°C the last components of the starch are enzymatically released from the spent grains to reduce the viscosity of the mash, which facilitates the lautering process.

Step 6: Checking the original gravity

The original wort is measured to check the dissolved sugar during the mashing process. This value essentially indicates how much sugar has been extracted from the malt and is crucial for determining the alcohol content of the beer. An initial measurement of the original gravity at this point provides an indicator of how much water can be added to achieve the target original gravity for the planned beer.

The brewer usually aims for a high malt yield and maximum utilisation of his kettle, which he can only determine by measuring the original gravity.

By keeping a detailed brewing log with exact quantities of malt and water and by taking measurements, the brewer can calculate his yield and determine the quantity of malt and water for the desired target original gravity in future.

Find out more about measuring original gravity here.

Final remarks

The mashing process is a central step in beer production in which malt and water are converted into a mash to produce sugar. This sugar serves as a food source for the yeast during fermentation and has a significant impact on the flavour and quality of the beer. Careful control of temperature, resting time and wort yield monitoring are crucial to producing a high quality beer. With experience and dedication, brewers can master the mashing process and create unique beers that delight the palate. The mashing process is therefore the first step on the way to a great beer.

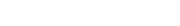

| EasyBrew Stainless Stell Brewing kettle 36L with discharge tap | Weck / Braumarkt cooker | EasyBrew SB 30P Brewing System | Grainfather G40 Brewing System | Speidel Braumeister Brewing System Plus 20L |

Digital Temperature controll | X | ✓ | ✓ | ✓ | ✓ |

Timer & Temperature settings | X | ✓ | ✓ | ✓ | ✓ |

Automatic stirring /Circulation | X | ✓ | ✓ | ✓ | |

Integrated Lautering | ✓ | ✓ | ✓ | ||

Recipe automation | X | X | ✓ | ✓ | ✓ |

Pre saved recipes | X | X | X | ✓ | ✓ |

PID-Heating control | X | X | X | ✓ | ✓ |

Cooling jacket | X | X | X | X | ✓ |

Possibility to ferment | X | X | X | X | ✓ |

Size (Hx⌀) | 38cmx35,5cm | 35cmx30cm | 79cmx40cm | 72,5cmx55,5cm | 60cmx40cm |

Cleaning | By hand | By hand | Cleaning solution + pump | Cleaning solution + pump | Cleaning program |

Price | 124,95€ | 199,95€ | 495€ | 1.349€ | 2.295€ |