Brewing non-alcoholic beer yourself

A hobby brewer who likes to drink beer also has to drive to work or has friends who prefer a brew without alcohol. Wouldn't it be perfect to have a home-brewed non-alcoholic beer in the house?

It can be done, but it's something for hobby brewers with more experience and equipment. So, how do you make a beer alcohol-free?

Get rid of the alcohol - but how?

Clearly, the alcohol must either get out or it must not get in in the first place.

In the first case, the alcohol can be removed with some technical effort by evaporating it under negative pressure or separating it with membranes. This even works until the beer contains only 0.0% alcohol. These methods sound like those used by large breweries, and that's exactly the case. Even in brewery groups, there are only a few such plants that produce alcohol-free beer for all group brands. Moreover, these beers are often quite empty and watery, because alcohol adds body to the beer and is a good flavor carrier. Moreover, they are even slightly hypotonic, contrary to the advertising for isotonic non-alcoholic beer.

We have known the older method in Germany since 1895, when beer with a very low alcohol content was first developed in Flensburg. In the USA, the first beers of this type arrived in 1919 with Prohibition. In both cases, this was soon over, because on the one hand the quality was lacking due to susceptibility to infection, and after the Prohibition the market for this beer was also quickly gone. The legal limit of alcohol was achieved by stopping the fermentation of the brewer's yeast so that it only converts about 10% of the fermentable sugar to alcohol. Incidentally, these beers are again usually slightly hypertonic for athletes. Many current varieties are even a mixture of both processes.

Is non-alcoholic the same as 0.0%?

A clear no. Today, the limit for beer is 0.5% alcohol volume. In the past, it was even 0.1%, but some fruit juices are up to 1% due to natural fermentation. However, this must only be declared for beer and you may only write 0.0% on it, if it is really true.

How do you reduce alcohol production?

Stopping or slowing down fermentation before it reaches 0.5% would therefore be the means for the ordinary brewer to prevent the alcohol from getting into the beer in the first place. This involves either filtering off the yeast at the right time, which requires a very fine filter, or directly inactivating the yeast by heat or cold. Sometimes yeast is also "glued" to nutrient media and thus immobilized, which means that not as much sugar gets past the yeast for fermentation.

These beers are usually very sweet to drink, as a lot of unfermented sugar, mainly maltose, is left behind, and this smells like a honey-like wort and doesn't really taste like beer. The process works best with Hefeweizen, where a little more sweetness is desired and harmonizes very well with the fruity flavors of banana from fermentation.

For hobby brewers it is best to use a special yeast.

Now we need to discuss a few details. Normal brewer's yeasts can process sugars with up to four molecules in a chain. This is the bulk of the sugar in the beer wort that the brewer produces from the malt. However, there are still yeast strains, for example WSL-17 from the Weihenstephan yeast bank (available at Braumarkt Hamburg), which can only process single to double sugars (glucose, fructose, sucrose). The explanation for this is quite simple. Fermentation means the formation of alcohol (ethanol) and carbonic acid (H2CO3, i.e. CO2 dissolved in water) from glucose to obtain energy (ATP, adenosine triphosphate), which the yeast cell needs to live. The yeast cell cannot easily use other types of sugar for itself. The common brewer's yeasts are therefore more advanced and have transporters that can transport the aforementioned two-sugar maltose into the cell and enzymes that break it down into glucose.

These particular types of yeast are very interesting for brewers and hobby brewers, because it is not necessary to inactivate or filter the yeast to stop fermentation. It is enough to prepare a wort that does not contain more sugar than the yeast needs to process for a maximum of 0.5% alcohol. In addition, the yeast is not stopped in the middle of fermentation, but can convert other fermentation by-products beneficial to the beer bouquet.

So how do we do this?

The hobby brewer is not so much interested in the specifications for commercial beers, so anyone can add more alcohol to the beer without it becoming more alcoholic than a lightly fermented apple cider of just under 1% vol. In France, Spain or Italy, this beer could even be declared alcohol-free.

If you still want to be under the limit or even have to do so commercially, you must not feed the yeast too much for a maximum of 0.5% alcohol in the finished beer. Thus, a low original wort with little fermentable extract must be formed. That's exactly the problem, because a normal original wort of 12°P, i.e. 12% dissolved extract from malt and hops in the wort, would be fermented by a normal brewer's yeast to about 80% and form about 5% alcohol. But our low-fermenting yeast would still produce up to 1.3% alcohol from that. So we have to go down with the original gravity. How far depends on the recipe and the malt analysis, because today's malts are already very rich in fermentable extract ex works. What pleases the brewer in a highly fermented beer is quite a problem in non-alcoholic beer. Because fermentation levels of not infrequently 21% mean you have to go below 5.7°P original wort, which is really little. A good non-alcoholic needs every bit of flavor in the water, especially from the malt. Ideally, you'd have a batch of malt with just over 80% extract at fine grist (it says in the malt analysis), then an original gravity of 6.5°P would be possible. Nowadays, it is almost impossible to get less than that with basic brewing malts. The exact distribution of the sugars is nevertheless not known and therefore it is absolutely recommended to make a quick fermentation test in order to be able to cool down in time before reaching the 0.5%vol. in case of a too high fermentation degree.

The recipe is what makes the non-alcoholic a full-bodied beer in the first place.

Malt:

Now it comes down to the choice of malt. Pilsener malt will produce a very light and lean beer at this low original gravity. The darker Munich malt hits the familiar color right off the bat and contributes more full-bodied flavors. Of course, melanoid malt also helps with color and delicate fruity flavors or roasted malts add a slight complexity or kick of roastiness to a non-alcoholic porter or stout. Oat malt or spelt and wheat malt give a subtle sweetness and creamy texture on the tongue, but make the beer very cloudy. 5-10% chit malt helps in lowering the amount of fermentable sugars if the base malt brings too much fermentable extract. This can increase the original gravity by 0.1-0.3°P.

You should stay away from caramelized malts, they introduce a sweetness that many criticize in non-alcoholic beers, even if it can improve the body.

Mashing:

It can be a short brewing day, as it is recommended to omit the maltose rest or to keep it very short at higher temperatures (67-68°C, 5-10 min.). When resting below 70°C, the β-amylase forms the maltose that makes up the sweet spicy taste that many do not like in non-alcoholic beer. Consequently, if we rest only above 70°C, very little maltose is formed and more dextrins, which also contribute to the body. It is not necessary to mash longer than 10 minutes or until the normal iodine level is reached. After that, the enzymes should be deactivated at 80-82°C, so that during lautering by cooling definitely no enzymes can survive to form more sugars. A bit of pithy flavor due to leaching of the husks (the magic 80°C limit) is even desirable here. For stout fans, a note. Roasted malt will hardly be able to transfer color into the finished beer during this short rest.

Hobby brewers have some interesting possibilities that are rarely available in the industry.

Hops:

An improvement of the very lean body on the malt side can also be achieved by the hops.

On the one hand, I recommend a significant bitterness of over 40 bitter units, since a tart finish reminds one of beer and distracts from the lean body. In addition, the bacteriostatic effect of the hops also increases stability against some fermenting bacteria.

The old hop varieties with little Humulon (alpha acid), such as Hersbrucker, Mittelfrüh, Spalter Select or Tettnanger, are particularly recommended. These also bring in many other fractions of the hops when used heavily for bitterness, emphasizing a full-bodied fine tartness.

Now the question is which beer style to aim for. You'll find two sample recipes in the margin of this article. A simple Kellerbier, Porter or Stout can be achieved with the right malt combination and a slightly more hop. A hop-flavored Pale Ale or IPA needs an appropriate hop addition. The bittering should still be done with the old hop landraces. In addition, an intensive late hopping or whirlpool hopping so that the hop trub can be separated properly. Cold hopping adds even more fruit flavors, preferably after primary fermentation with P45 pellets (sometimes called CryoHops). This contributes less mouthfeel and tannin from the leafy greens and more aroma. High-intensity varieties, such as Mandarina Bavaria, Simcoe, Mosaic, Centennial and similar aroma hops are recommended for a stable hop aroma. They should definitely have a longer contact time with the beer during storage. A dose of 1.5 to 3g/liter should be sufficient. In addition, it helps to include the selected cold hopping variety already in the whirlpool to harmonize the aroma and make it storage-stable.

The yeast hardly ferments, with consequences

Fermentation:

Due to the low fermentation activity, there is not only little alcohol, but also little CO2 and a low drop in pH, which normally drops from 5.5 to 4.5 and is now perhaps at 5.4. Lactic acid must be added here to bring sweet and sour back into balance and give the beer better acid protection against infection. The lactic acid should be added after boiling. Before hop boiling or when using sour malt, there is poor enzyme activity during mashing and much lower utilization of hop bitterness (alpha acid) during boiling. Simply add the right concentration at the end of boiling by checking the value with a pH meter (in a pinch test strips with a small scale). But be careful! With 80% lactic acid, the pH value drops very sharply with just a few drops in hobby brewing quantities.

After boiling, cooling must be done quickly and as much covered as possible, so that no yeasts or fermenting bacteria from the air contaminate the wort. Because our yeast will leave a lot of nutrients. Very important!. A cooling wort loses volume and a negative pressure is created in the cooling vessel. That is why the CO2 bottle or a sterile air filter must be connected to each air inlet, so that no contaminated air is sucked in. This is the most common source of failures!

The propagation yeast (for details, see the 'Hefe Propagation' image below) must then be added in an appropriately clean manner. So disinfect all surfaces and attachments at the opening and run an open flame (e.g. gasburner) at the same time. Ideal is the transfer from the laboratory bottle/propagation barrel with sterile air into the fermenter.

The recommended fermentation temperature of the yeast bank is 14 - 15°C, but higher temperatures are possible and a slightly more intense pleasant yeast bouquet is produced at 20°C.

During fermentation, only a little CO2 is produced by the yeast. However, this is enough for a normal beer and must be used immediately. Therefore, fermentation should not be done in the fermentation bucket, but directly in the keg (KEG), so that the CO2 can dissolve. The pressure is just right for the beer and there is practically no 'krausen', so no additional rising space is needed. So rinse the keg with CO2 beforehand and fill it to the brim. If you have a bung valve, you should close it right away. Subsequent carbonation is only possible with the gas cylinder, but not with sugar (= too much alcohol). The excess yeast accumulates at the bottom of the KEG and can simply be discharged with the first pour when tapping. With bottle fermentation, an undesirable sediment forms at the bottom of the keg, releasing carbon dioxide in a strong foaming manner when the keg is opened.

To be on the safe side, the finished beer should be pasteurized, i.e. heated at 65°C for about 5 minutes. If not, normal yeasts can increase the alcohol or over-fermenting beer pests can even cause the bottles to explode.

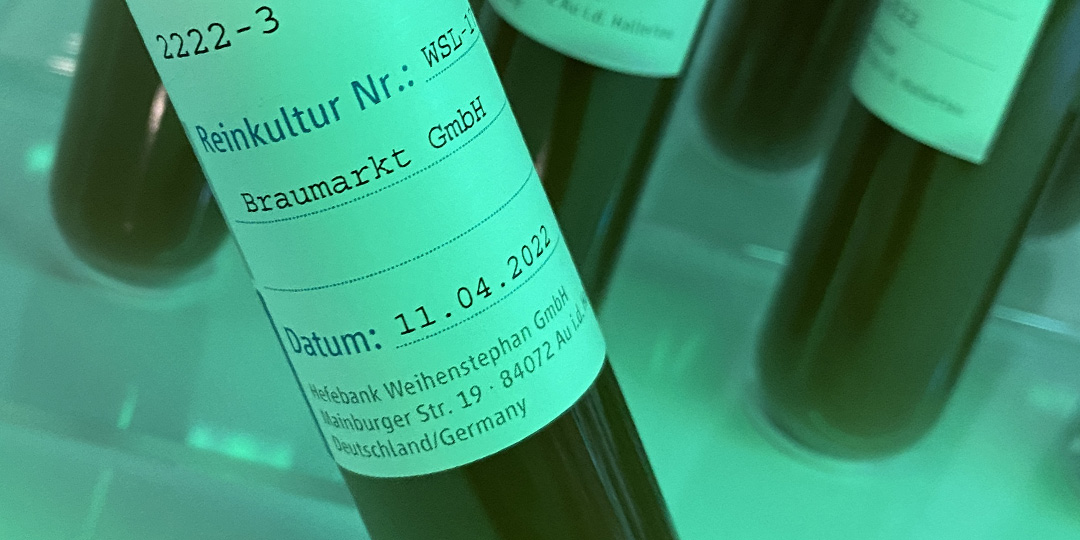

Yeast propagation

- When the yeast is liquid, it comes as a 40ml starter. For example, the WSL-17 from the yeast bank Weihenstephan (Available at Braumarkt Hamburg).

- An Erlenmeyer flask or lab bottle should be made clean and disinfected. A pressure cooker can be used to autoclave the flasks and attachments (pressure sterilization).

- A magnetic stirrer would be required in any case to aerate the yeast for propagation.

- The propagationwort should be 10-12°P. Half of this should be glucose, as the yeast cannot process maltose. The wort contains important nutrients for propagation. We obtain these from our last brew or from dry malt extract. Everything must be boiled and cooled. Caution: air is sucked in when the bottle cools, so be sure to screw on a sterile filter or stuff it down the neck in absorbent cotton disinfected with alcohol.

- Disinfect everything (including hands) with alcohol. Keep it near an open flame, because hot air rises with all foreign yeasts/bacteria and flamed air is sterile anyway.

- Then add the yeast to the propagationwort, cover with a lid or absorbent cotton and turn on the magnetic stirrer. Room temperature is sufficient.

- Every day, the amount is then increased tenfold with fresh propagationwort until you have reached about ten percent of the amount of original wort.

- Ideally, the propagationwort is transferred to the keg with the original wort using sterile air or CO2. Alternatively, use a sterile funnel for filling and check whether the keg is really tight after screwing by turning it upside down.

Alcohol-free brew checklist for hobby brewers

- low-fermenting yeast, e.g. WSL-17 (available at Braumarkt Hamburg)

- conical flask (Erlenmeyer), better a laboratory flask and magnetic stirrer;

- a Bunsen burner or a simple gas burner with cartridge for a tenner from a hardware store;

- dry malt extract and glucose (often sold as dextrose);

- a fresh and intensively sterilized keg (KEG);

- cleaning alcohol, e.g. propanol, ethanol or mixtures thereof;

- optimally also cleaners based on acid and lye (in the drugstore there is pure citric acid and possibly washing aids from pure sodium percarbonate), without surfactants and enzymes;

- lactic acid or similar to adjust the pH;

- calibrated pH meter, or test strips with small scale between pH 4 and pH 6;

- a pronounced obsession with cleaning!

Recipe non-alcoholic Pils / Pale Ale

- 100% Munich malt (15 EBC)

- At approx. 82% extract / fine grist, target original wort at 6°P, if necessary 10% chit malt to increase original wort by 0.3

- Mashing & resting at 72°C to iodine standard

- Mashing at 80-82°C

- Bitter hops Tradition/Hersbrucker/Mittelfrüh up to >40 IBU

- After end of boil, adjust pH to below 4.5.

- For the Pale Ale: Whirlpool hopping Comet/Simcoe/Amarillo/Mosaic at 3g/l.

- Main fermentation directly under pressure, e.g. in KEG for CO2 binding.

- Take a quick fermentation sample for final fermentation rate

- If the final fermentation degree of the quick fermentation sample is too high, cool down the fermentation barrel in time (1°C).

- If necessary, add hot extract (hop tea at 80°C) after fermentation or cold hopping with 1.5-3g/l

Recipe non-alcoholic porter / stout

- 50% Munich malt (15EBC) or Vienna malt (9EBC) (if necessary 5% smoked malt, 45% Munich malt).

7% Caramel flavor (50 EBC), 10% Biscuit Malt (50 EBC), 30% oat/spelt or wheat malt, 3% dark roasted malt (1400 EBC) - At approx. 82% extract / fine grist original wort 6°P if necessary 10% chit malt to increase stw. by 0.3

- Mash in at 65°C & rest for 10 min.

- Resting at 72°C until iodine-normal

- Mashing at 80-82°C

- Bitter hopping 35-40 IBU with Smaragd

- After boiling adjust pH to below 4.5.

- Darken color further with color beer if necessary

- Main fermentation directly under pressure, e.g. in KEG for CO2 binding

- Take a quick fermentation sample for final fermentation rate

- If the final fermentation degree of the quick fermentation sample is too high, cool down the fermentation barrel in time (1°C).